Mobile 3C digital stamping parts are crucial components in the production of high-tech devices These parts are designed for precision and durability ensuring that electronic devices perform reliably and efficiently in various applications from smartphones to wearables

Cellular 3C electronic stamping parts are critical components that significantly affect the general performance connected with electronic devices These parts be the building blocks pertaining to complex assemblies in smartphones tablets and other digital solutions ensuring every device operates smoothly as well as efficiently The precision by which these parts usually are manufactured determines how good they fit together within this device minimizing the risk associated with mechanical failure or power issues Furthermore high-quality rubber stamping parts contribute to much better heat dissipation structural honesty and component alignment each one of these being crucial for functionality and durability in electronics In prioritizing on quality mobile 3c digital printin manufacturers can meet expectations from tech savyy consumers today.

Indeed, precision is very important when making mobile 3C digital stamping parts because it determines how well electronic devices work and their reliability These components are used in smartphones, tablets and other digital products where even slight variations can lead to failure or shorten lifespan To achieve this level of accuracy, they have to use advanced production methods such as high-speed stamping or laser cutting which ensure that every single piece is made according to exact dimensions Not only does this method ensure that electronic devices function correctly but also contributes towards their longevity and user-friendliness Therefore precision remains one of the key factors for success in modern consumer electronics characterized by mobiles for the 3Cs

The mobile 3C digital stamping parts manufacturing industry is always changing, as it requires newer and better ways of production This means that innovative thinking needs to be applied here so as not to lag behind the fast pace of mobile technology development Manufacturers strive for higher quality products and more efficient production methods through such means as working with new materials that provide greater strength combined with flexibility or using automated processes that speed up their work Even computer aided design (CAD) systems along side simulations are integrated into the process flow which allows accurate prototyping followed by testing hence leading to improved product outcomes These advancements are necessary since they help enable these components meet current complex requirements posed by modern electronics.

The manufacturers have been using customization more and more for their mobile 3C digital stamping parts because they want to cater for many electronic gadgets’ specific requirements. Customization has gained popularity due to variation in mobile technology ranging from smart phones to wearable gadgets which demands unique design features as well functional needs fitting components Custom made production enables the firms not only produce accurate and strong pieces but also ones which are best suited for a given use; this may involve shapes sizes or even material properties These days, companies can make personalized stamps through such improved methods as rapid prototyping CNC machining among others that help them come up with good-looking items that function well too Therefore, these businesses customize everything around them so that their products can be differentiated easily amidst stiff competition within an industry that thrives on speed coupled with innovation.

Dongguan CHSUX Precision Technology Co., Ltd., a 17 year OEM and ODM manufacturer of RF Connectors in Dongguan City, specializes in R&D, production, and sales of precision hardware, RF Connectors, coaxial cables, cable assemblies, antennas, auto components, and microwave products. With a comprehensive range of RF Coaxial Connectors like SMA, SSMA, SMB, and more, we meet diverse customer needs.

Equipped with advanced automatic and semi automatic machinery, we maintain a robust R&D team and production chain. Our commitment to quality is evident through our adherence to international standards like IATF 16949, ISO 9001, and ISO 14001.

We invite customers and business partners worldwide to partner with us for mutual growth and success.

Consistent high-grade materials ensure customer satisfaction.

Efficient logistics support timely worldwide deliveries.

Attractive rates make bulk orders more cost-effective.

Responsive service enhances client relationships and trust.

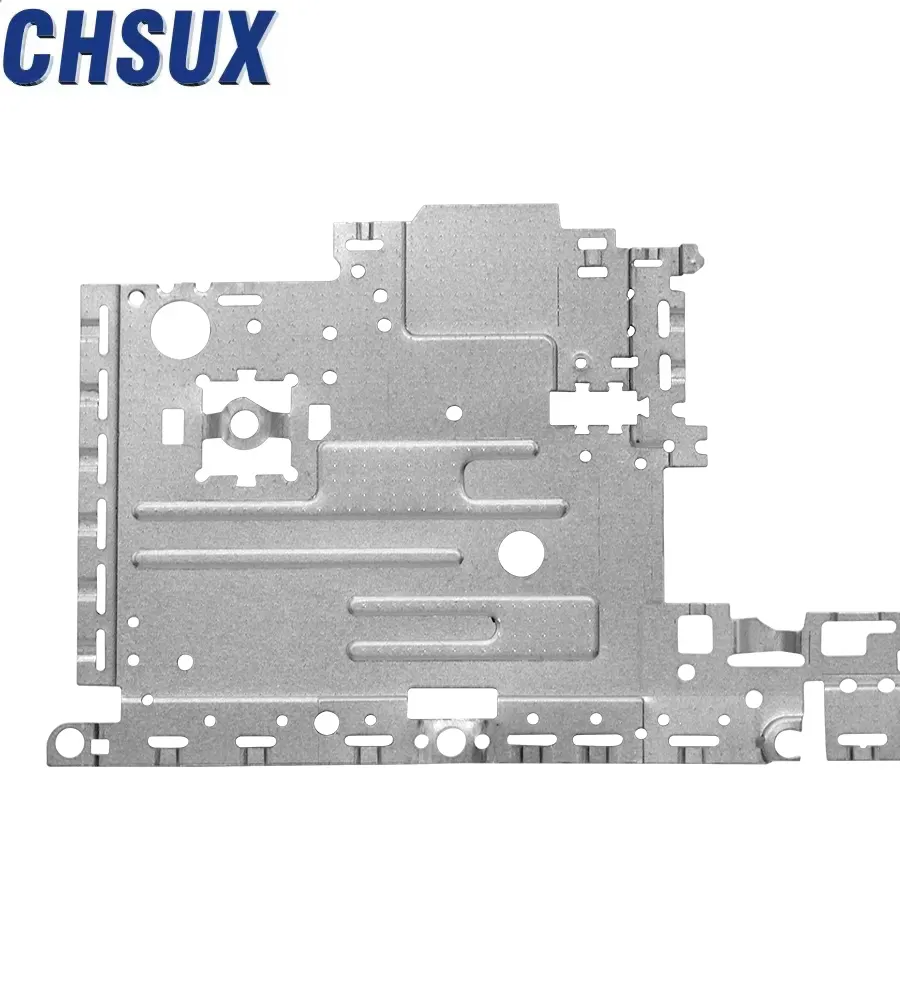

A mobile 3C digital stamping part refers to a component produced through the stamping process, used in mobile devices and 3C (computer, communication, and consumer electronics) digital products. These parts are typically made from metals or alloys and are essential for the structural integrity and functionality of electronic devices.

The manufacturing process involves pressing a metal sheet into a specific shape using a die and a stamping machine. This method allows for high precision and mass production of components, making it ideal for the fast-paced electronics industry.

Common materials include stainless steel, aluminum, and copper alloys. These materials are chosen for their durability, conductivity, and resistance to corrosion, which are crucial for the performance and longevity of mobile and digital devices.

Stamped parts are vital because they provide the necessary strength, precision, and electrical conductivity required in mobile 3C devices. They also contribute to the overall design and compactness, ensuring that devices remain lightweight and durable.

Yes, mobile 3C digital stamping parts can be customized to meet specific design and functional requirements. Manufacturers can adjust the die and material selection to produce parts that fit unique product specifications, allowing for innovation and differentiation in the electronics market.