1. First optimize the product 3D design

To increase the efficient use of metal materials for automotive stamping parts, the design of the product structure must first be optimized in order to take into consideration its process features and to enhance the economical efficiency of its design. In designing the product, there should be a consideration of the parts that are going to be used to make the automotive stamping parts and the composition of the structures of the parts, and each of the designs of the components should be done in a way to minimize the metal materials needed in total.

2. Choose a sensible process method

Seam in all the details for metal plates for automobile stamping parts for optimal use, the process method must be selected as well. In the first place, when producing a part, one must perform a thorough and adequate selection of all pertinent materials, and afterward use a definite processing technique appropriate for those materials and maximize output while controlling quality. More specifically, it consists of the following main processes:

(1) Prefer punching with little or no wastage. After establishing the product design plan and in the selection of materials, particulars should be preferred that will not result in or have minimum wastage for punching. If such materials are in short supply and cannot satisfy the requirements of product structure, appropriate designers may modify and optimize the product structure in relation to the availabilities of such materials in order to conserve materials.

(2) Ensure that there are clear procedures for process layout. During product process method design the factors in consideration should include several varying scenarios, develop as many alternatives as possible, screen, and be able to identify the most appropriate layout alternative.

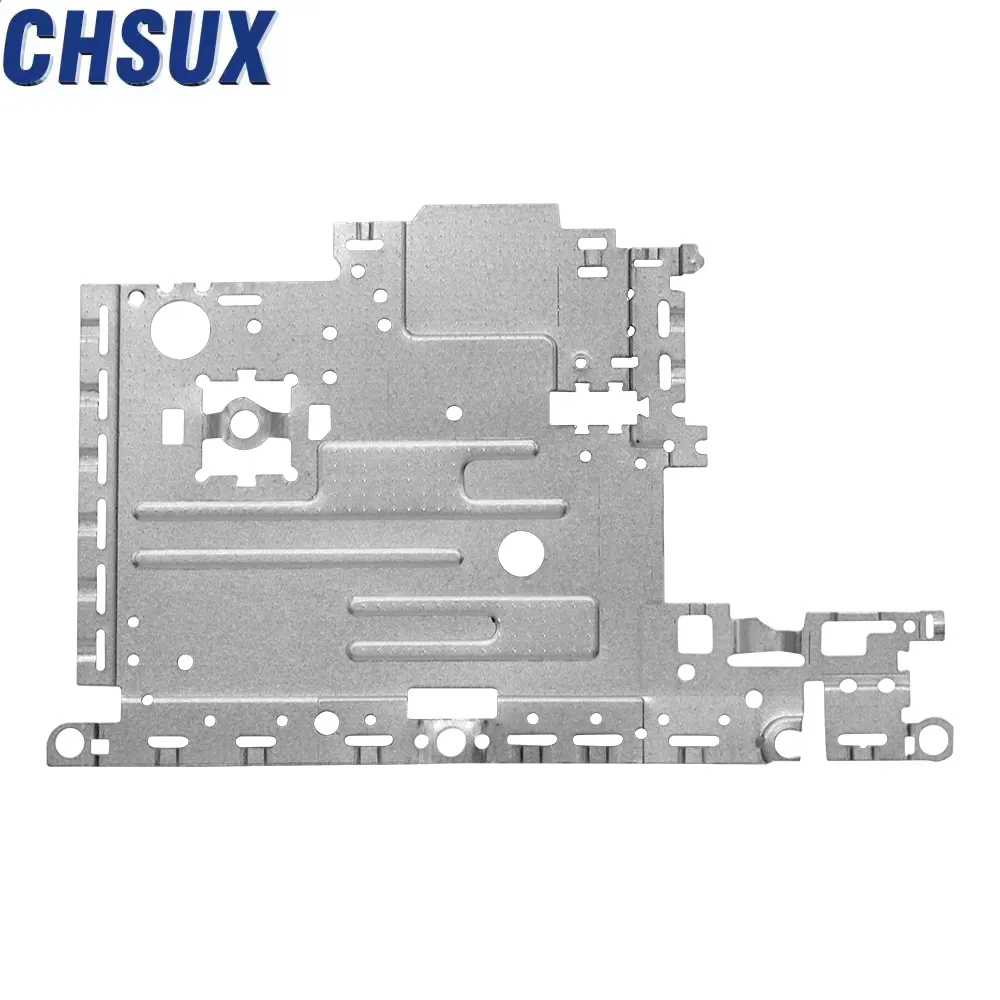

(3) Application of the nesting method is logical. At the stage of the design process of automobile stamping products, all specific requirements of direction, dimension, configuration and other characteristics of the part materials used must be taken into account. In the void area of the part, nesting treatment is carried out and another part is obtained, and the void area of this part is removed to obtain two parts. This way, it is not only possible to reduce the effective working time significantly and increase the efficiency of the work processes, but also optimize the utilization of raw materials and enhance the efficiency of production of automotive stamping workpieces. Also, when designing the sheet metal shear layouts in the nested process, it is possible to use technology means in the nesting process to improve the utilization of metal materials.

3. Safely keep the mold process card for the particular sequence of operations concerning the attachment of the template plate to the mold as well as the parameter setting of the mold pressure, create the appropriate factory badge to be placed on the injection mold or on a rack adjacent to the press in order for the pressures to be quickly accessed and the relative height of the installed mold adjusted. By cascoding practical operators’ quality understanding to the operators’, it reduces the frequency of self, inter and final inspections in molds production. It reduces the chances of quality defects and improves production quality consciousness and product quality.

The service life and efficiency of the molds can be improved by keeping the molds manufactured every time. In the case of mold imperfections, the same needs to be remedied through immediate action and the repairmen are involved in cutting and welding so as to rectify the defect. In the case of a high-demand product, several sets of molds can be opened for use provided the profits are assured.